Compressor Skids

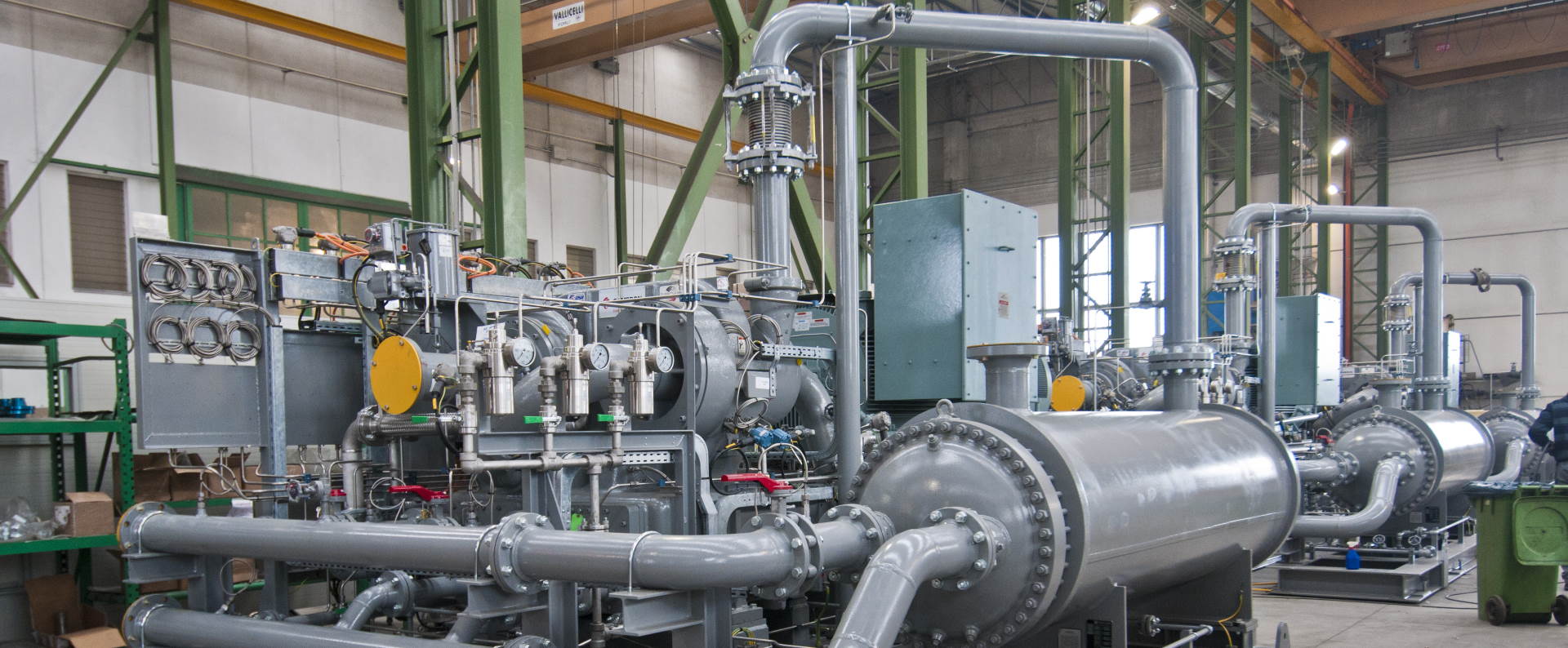

F.B. SPA assembles gas and air compression systems reciprocating, centrifugal, screw and liquid ring type, for customized applications.

In our Workshop, according to a controlled process that develops entirely within the company, are assembled systems that, integrating the compressors of our Customers powered by electricity or gas engines, allow to realize turnkey solutions on skids, complete with pipes, supports, valves and instrumentation. The systems are designed and built according to international standards, as ASTM, ASME, API, BS, DIN, UNI, AWS, ANSI, EN and PED. Explosive risk standards are applied in areas with particular hazardous properties and the following applicable certification standards are met: EMC/EMI, CU-TR (ex GOST), BV, DNV-GL, ABS etc.

Our jobs

LUBE OIL UNITS 614/618

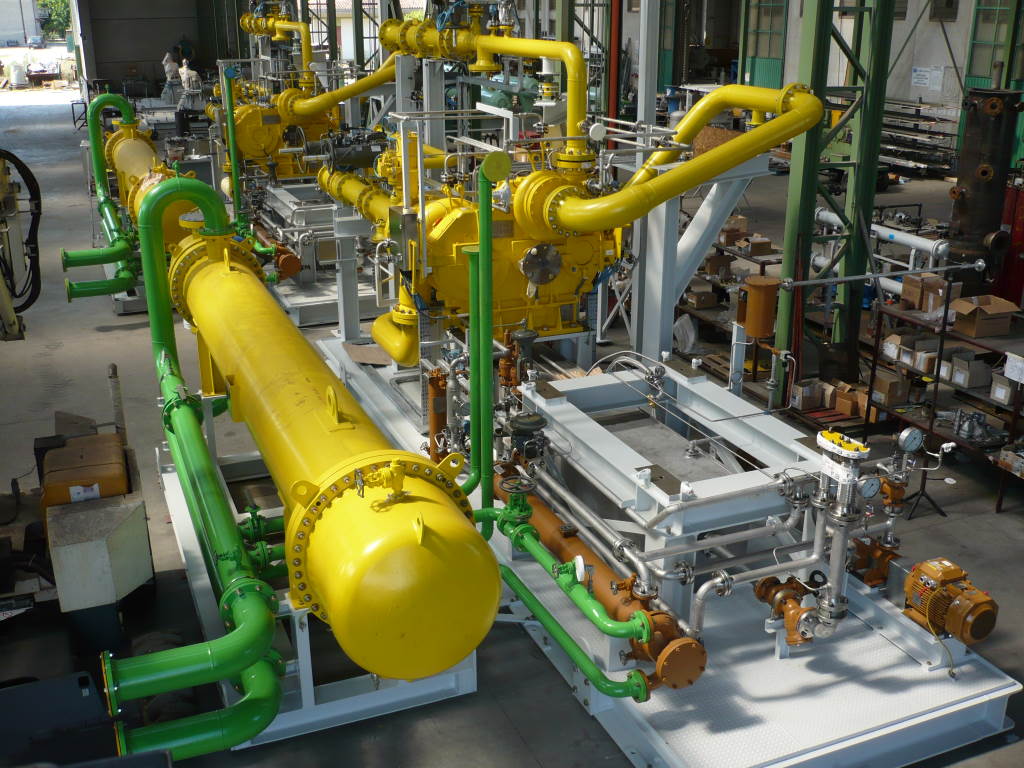

Lube Oil Units, Seal and Control Units are designed to supply pressurized lubricating oil to different kinds of industrial systems. They include pumps, heat exchangers, filters and control instruments.

Lube Oil Units (skids) inject oil at controlled temperature into the bearings before, during and after the compressor operation.They are assembled on steel structures and designed to be safely transported at Customer Site. The range of the units assembled in our workshop include:

Lube oil systems for Motors

Lube oil systems for Compressors

Lube oil systems for Gas Turbines, Steam Turbines and Generators

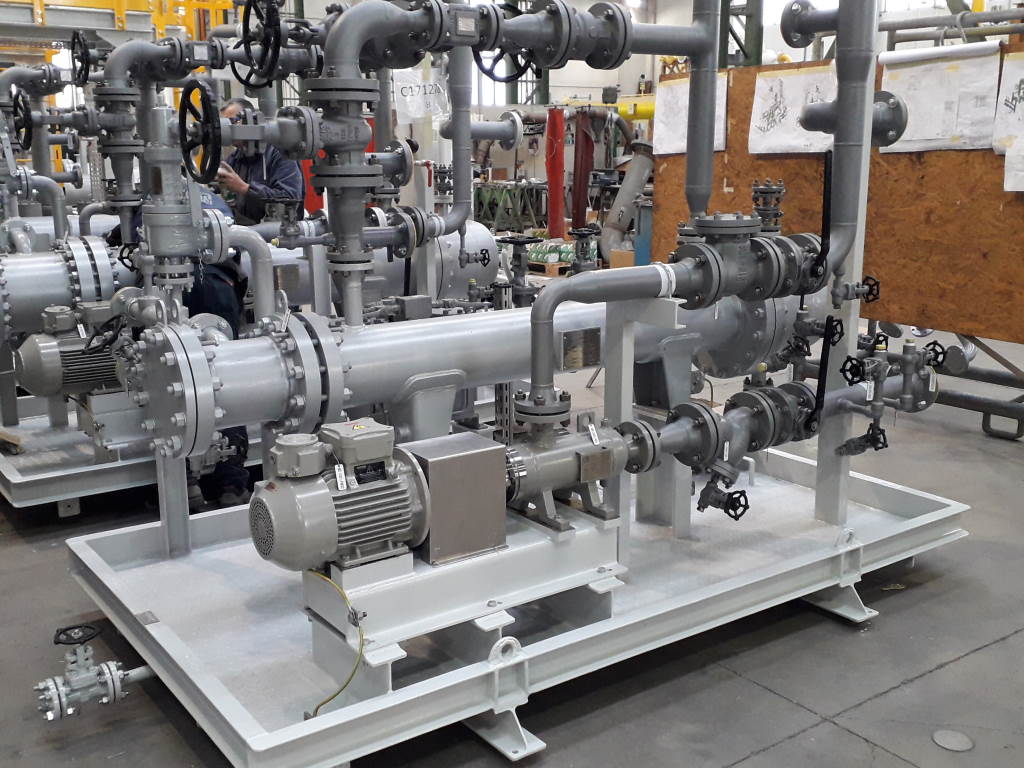

COOLING WATER UNITS

Cooling water units for reciprocating and centrifugal compressors, including pumps, tanks, heat exchangers,filters and control instruments

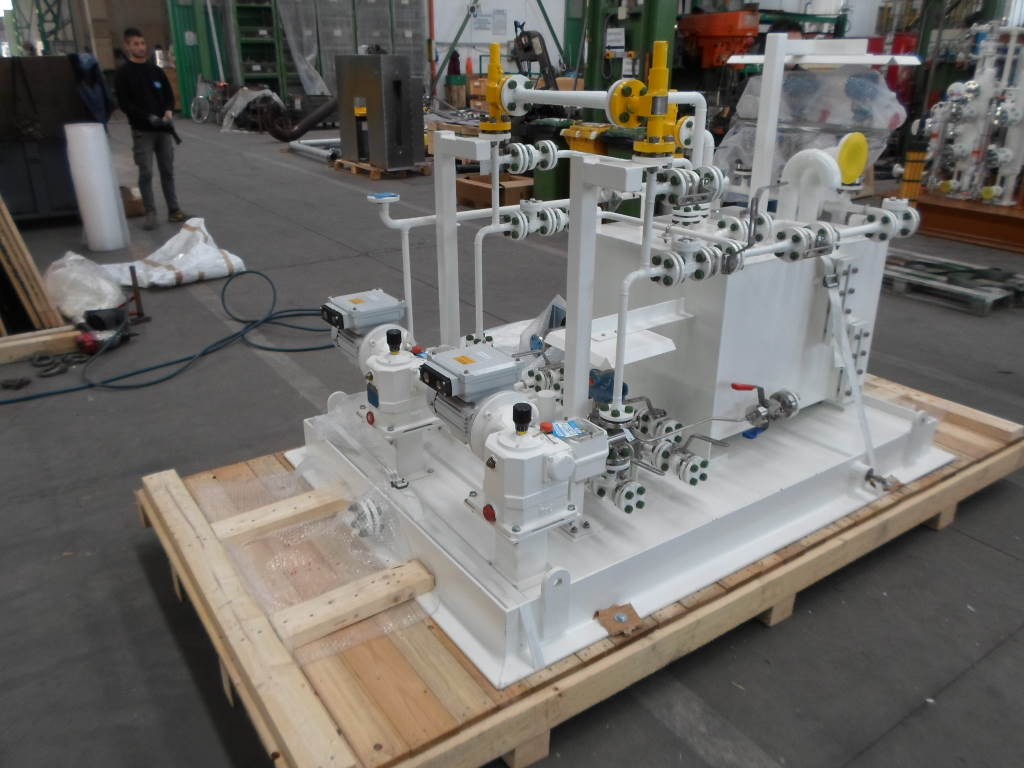

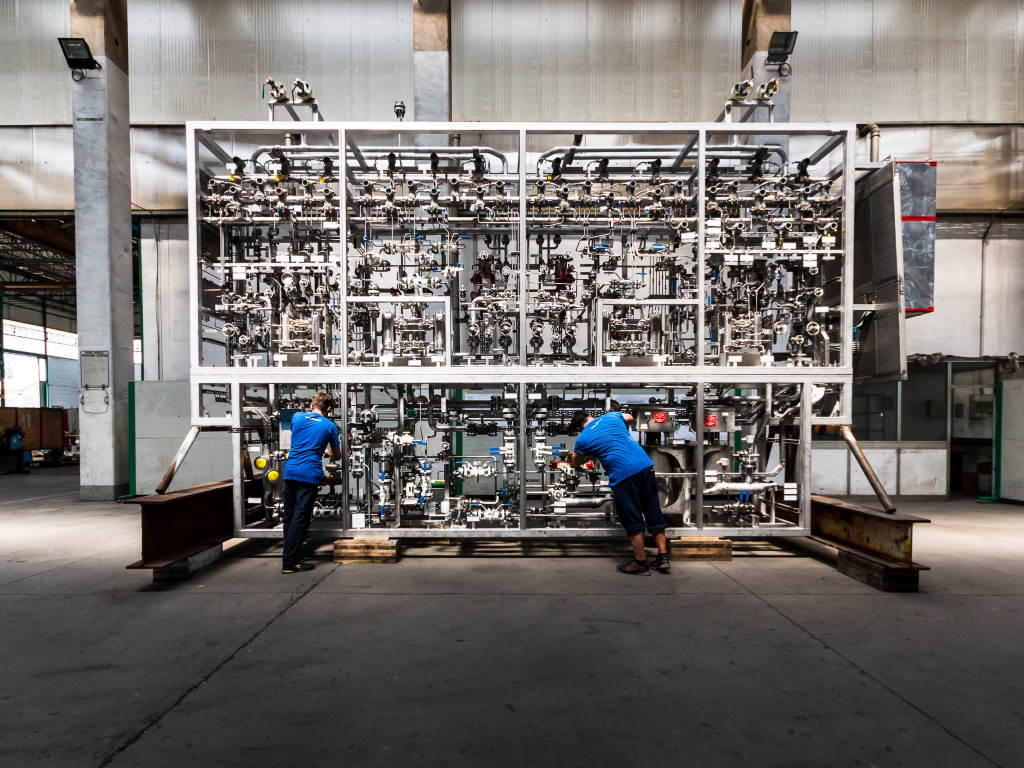

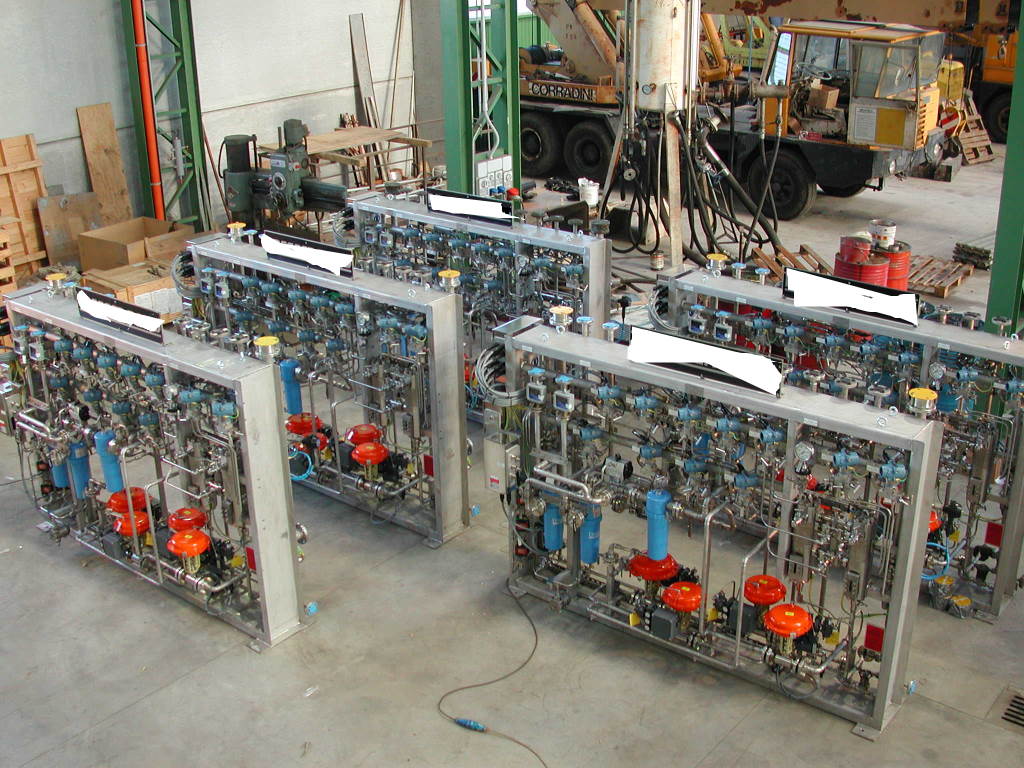

SEAL GAS PANELS

Seal Gas Panels are manufactured in accordance with ISO 10438:2008 Part 4 and API 614,5° Edition, Chapter 4.

These panels include instruments, manifolds, filters, piping and tubing.

They are designed and manufactured in compliance with applicable codes and standards and in accordance with Customer specifications.

- Pressure values up to 550 bar;

- Design temperature from-50 to +200 °C

- Atex Zone 1, Zone 2 components

- NACE MR01/75 components

- Filtration grade up to3 µm

- Structures in carbon steel and stainless steel

- Piping in stainless steel (304L, 316L, 321, etc.), low temperature carbon steel, duplex, Inconel or Sanicro

- Tubing with double ferrule fittings

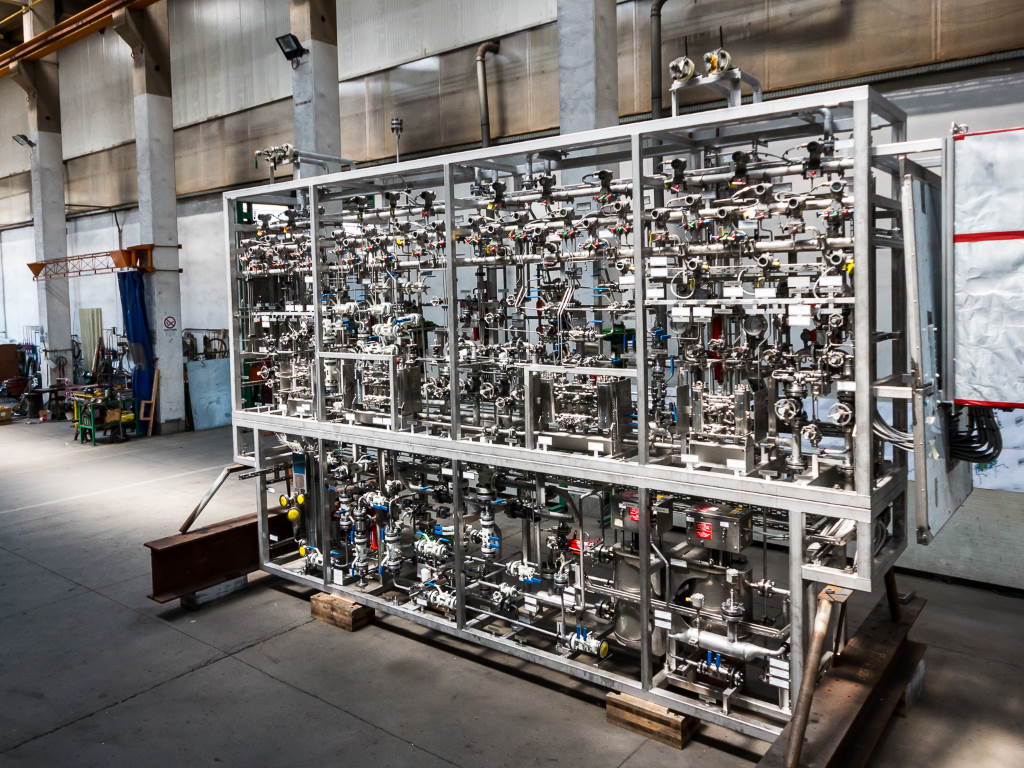

GAS TREATMENT SYSTEMS

These units are designed in order to avoid liquids, solids and liquid aerosol inlet inside natural gas driven motors and turbines. The natural gas is overheated in order to avoid the formation of liquid condensate and its consequent insertion inside the combustion chamber of motors and turbines.

The pre-heating system is made by means of bundle tubes/electrical heat exchangers or water-bath heaters.

The final filtration required assures the specific quality of motor/turbine natural gas, so as to guarantee the proper duration and reliability of the system.

Our jobs

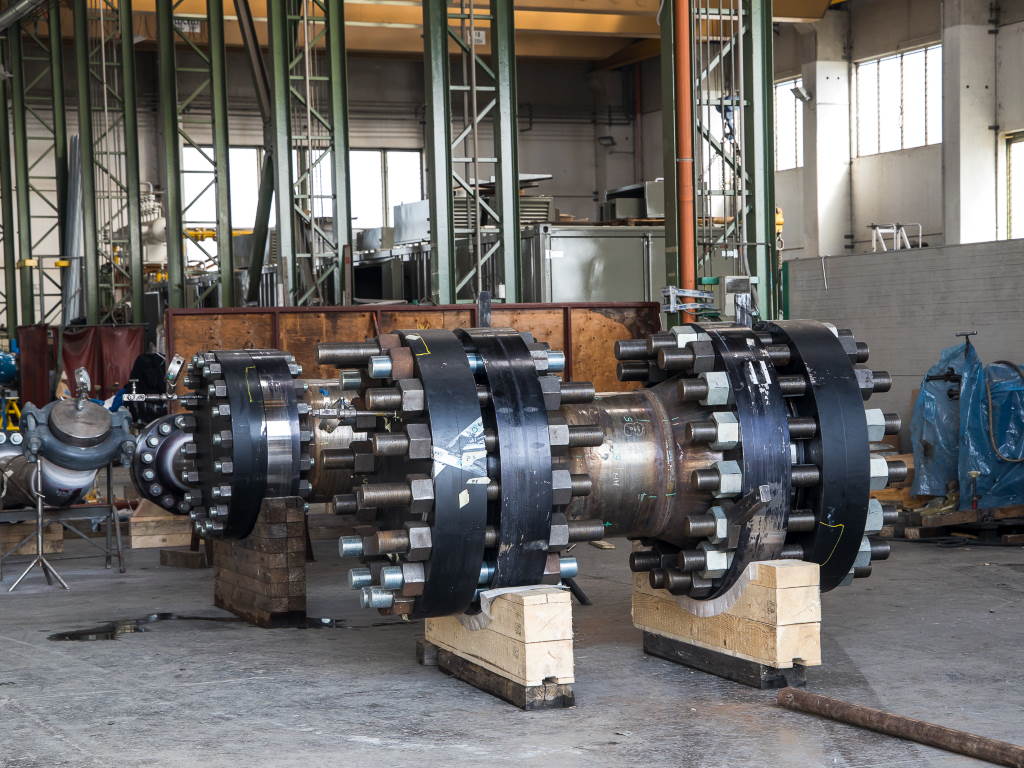

PIPING

Piping and spools assembly by means of precision welding machines.

Our welding procedures are in accordance with ASME B31.1, B31.3 for a large variety of materials, such as carbon steel, chromium-molybdenum-V (P91), stainless steel, duplex, super duplex, inconel and hastelloy.

PRESSURE - VESSEL

F.B. spa have long experience in fabrication of pressure vessels for the oil & gas sectors, designing and manufacturing many types of pressure vessel in a wide range of sizes and materials (carbon steel, Low temperature steel, stainless steel, duplex, hastelloy and many others) forboth ATM and High pressure, under PED-mod. H and ASME U-STAMP. Pressure vessels are entirely enginered, realized, tested, treated, coated and certified at our workshop.

BASEPLATES

Baseplates for off-shore and on-shore applications ar realized and machined in our dedicated area.

Approximate dimensions: L. 11m, H. 4,5m, W. 1,4m and weight up to 60÷70 tonnes.